ABOUT US

NARVAN Petro Gostaran Company is engaged in the field of oil & gas upstream or downstream by providing the engineering consulting, market research and development, with the technology transfer approach from international well-known companies.

As our especial oil well services, we provide nitrogen gas lifting operation by providing nitrogen generator unit (NGU)to inject to the wells during well repair or IOR/EOR projects.

NARVAN Company as a subsidiary of its shareholder (APIss Company), is an oilfield service company with the purpose of providing world class solutions to clients and operating well services by utilizing high technology equipment and professional crews in local area with a vision of being the largest service provider across the Middle East region. We believe passionately in our core values to provide our services with excellent quality, safe and reliable operations through a continuous improvement approach, to deliver on our commitments to clients with specific focus on protecting the environment where we operate.

FIELDS OF ACTIVITIES

NARVAN provide a full range of oil and gas well services to improve well production performance. Our efficient, reliable and integrated Service solutions can overcome every technical challenge and help you achieve maximum well production at the lowest possible lifting costs.

OUR SOLUTIONS

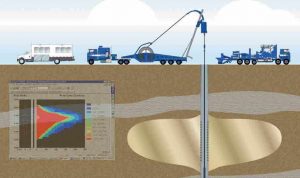

Nitrogen plays an essential role in oil fields development and oil well Servicing. We offer our services including nitrogen gas lifting, wellbore cleanout and jetting, fluid circulation, and nitrogen kickoff during repairing of low pressure wells or surface well testing jobs in order to flow back the fluid after acidizing or fracturing, flow back mud or injected fluids, drainage liquid for gas well and so on. Some of our solutions for oilfield owners are included as following:

OUR EQUIPMENT

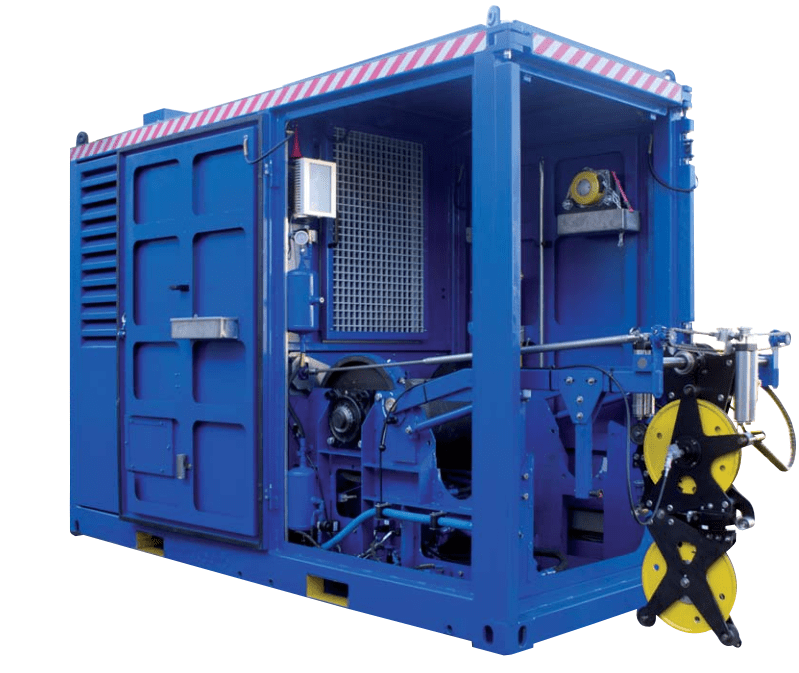

1- Nitrogen Generator Unit (NGU):

Our Nitrogen Generator Unit (NGU) is a membrane type trailer mounted nitrogen generator and injection unit equipped with original reputed brand components which deliver unlimited nitrogen gas with high purity and capacity in all environments and meets all oilfield clients’ requirements. Main Technical specification of ARIO NGU 1200 Turbo: 1200 Nm3/hr, 35 MPa, with a purity range of 95~99.5%.

2- Slick line Unit :

Our Slick line Unit is a skid mounted single drum Slickline unit capable of holding 25,000 ft of line and equipped with original reputed brand hydraulic system, transmission, diesel engine and Heavy duty drum shaft bearings which provide extreme performance with a wide range of line pulling and line speeds in all type operations and environments for setting downhole tools and meets all oilfield clients’ requirements.

OUR PROJECTS

Nitrogen Gas Lifting Services For NISOC Oilfield Wells

Year

2019-2021

Status

In Progress

Client

NISOC

Design & Engineering Consulting of Crude Oil Separation Unit for South Yaran Oilfield

Year

2020

Status

Completed

Client

Amin Petroleum Ind. (API) - PEDEC

Engineering & Management Consulting of Oil Terminals for Imam Khomeini Port, Rajaee Port, Bushehr Negin Island Port

Year

2017-2018

Status

Completed

Client

Sina Port & Marine Co.- PHP

Management Consulting of Development of ELGA Oil & Gas Well Casing threading Manufacturer

Year

2018

Status

Completed

Client

ELGA Co. - NISOC

Engineering Consulting of IRAN Deep Water Well Drilling Plan with Oil & Gas Well Drilling Approach

Year

2018

Status

Completed

Client

Science and Technology Vice-Presidency,

Contact Us

NARVAN PETRO GOSTARAN Co.

Address

Unit #9 , No. 38, Nesa St. Seyfieh St., Mirdamad Blvd, Tehran, Iran

Tel

+ 9821 26422341 , +9821 26422187

Fax

+9821 26423624

info@narvanpg.com

Website

www.narvanpg.com

Website Support and Maintenance Services zabani@apiss.ir